Cold Rolling

Outline of cold rolling

- The Cold Rollimg come into the market with the present fundamental principle in 1982 after many year's research. Since then It has gotten various improvements and total production come over 700 units, and it has gotten great evaluation. We always try our best to improve the machine based on these actual results.

- CRF takes the initial of Cold Rolling Former, and TCR is the machine made to have the meaning of Top of Cold Rolling. "V" means an upgrade, and the number shows the capacity of the machine. OR, IR, UC show the kind of the sizing device which the machine has.

- This machine forms rolling inside and outside of the cylinder-shaped work piece by mandrel and forming roller.

Work piece expands about 20% at the external diameter by form rolling. Sizing is done after form rolling, the work piece flows from the machine outlet. This actuation is done automatically from the entry to the outlet.

- This machine can provide very high productivity. The machine is composed of the body part and the attached device.

- As for the attached device, a pressure-oil tank are put separately.

- There are entry hopper, palette inversion machine, an elutriation, cooling, oil skimmer, cyclone separator, an instrumentation device, and so on as the special accessories besides that.

Types of Cold Rolling

With external straight sizing device ⇒ □□□-OR

With internal straight sizing device ⇒ □□□-IR

With external spherical sizing device ⇒ □□□-UC

With internal straight sizing device ⇒ □□□-IR

With external spherical sizing device ⇒ □□□-UC

Types of the machine distinguished CR work

CRF Series ⇒ CRF□□

TCR Series ⇒ TCR□□

CRF-V Series ⇒ CRF□□V

NCRF Series ⇒ NCRF□□

TCR Series ⇒ TCR□□

CRF-V Series ⇒ CRF□□V

NCRF Series ⇒ NCRF□□

The top end model featuring NC servo of cold rolling machine

- The cold rolling machine NCRF is the top end model featuring NC servo.

- NCRF is suitable for high-mix/low-volume manufacturing and can handle complex works that have been impossible to cold-roll so far. In addition to improved product precision, the time required for replacing trays has been remarkably reduced.

- Moreover, as with V Series machines, various settings such as feed speed, size input, and allowance input can be easily set using the touch panel monitor, because error messages will be output in detail, the place of failure can be detected immediately and necessary measures can be taken smoothly.

- Moreover, the operation efficiency has improved further because the monitoring function is employed and the item data can be stored. Since the data backup function is incorporated into data processing, the history of defective works and defective machining can be checked at a glance, therefore confirmation of the blank size and review of the setting values can be efficiently performed.

- Furthermore. this highly effective machine has employed the servo loader as the standard specification to improve the positioning accuracy and the loading speed. Additionally, an outside diameter measuring unit can be installed as an option. By setting up this unit between the rolling and the sizing points, defective works will not be sized, which makes the service life of the case longer and the time required for rolling will be shortened.

Strong points -Merits-

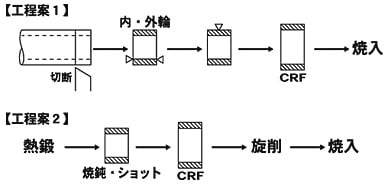

- Higher performance than conventinal methods

- Great improvement in material yeild

- 35% improvement in pillow bearing outer ring and 30-20% improvement in other inner and outer rings.

- Uniform high quality: The excellent metal flow, because of the cold roll forming, results in less distortion than heat treatment causes. Surface rouchness is better than 3S, and outer and inner ring raceways, radius, and other dimensions are very precise and stable.

- Tool life (roll and mandrel) is extended due to the cold forming process.

- The environment in the factory improved. (no mist, dust etc.)

- The number of machines needed is greatly reduced, resulting in reduced facilities costs.

- Electric power consumption is remarkably reduced. (Total electric power required for CRF120 is only 12.7kw)

- Low noise

- Cycle time is shortened.

- Short set-up time.

Cold rolling machines uses a method that depend on a competely new peocess. It greatly improves yeild, shortens cycle time, reduces labor costs, improves quality, especially metal engineering, and creates a better production environment. In short, the CRF/ TCR Series has numerous features that support high-performance production.

A form and main specifications

Item

| CRF-70

| CRF-120

| |

Max. forming force

| 7,000 kg

| 18,000 kg

| |

Capacity

| MAX. outside diameter

| Φ 72

| Φ 120

|

min. inside diameter

| Φ 15

| Φ 40

| |

feed speed

| 0 - 180mm/min

| 0 - 180mm/min

| |

Revolutions

| 125r.p.m

| 125r.p.m

| |

Motor

| Full roll drive

| 3.7KW, 1.5KW

| 11.0KW, 2.2KW

|

For hydraulic pumps

| 1.5KW, 3.7KW

| 1.5KW, 5.5KW

| |

For rolling oil pump

| 250W

| 250W

| |

Lubrication manual pump capacity

| 6ℓ

| 6ℓ

| |

Operating oil capacity

| 100ℓ

| 200ℓ

| |

Rolling oil capacity

| 50ℓ

| 150ℓ

| |

Machine height

| 1,400mm

| 1,800mm

| |

Necessary floor space

| 1,650mm × 1,150mm

| 2,000mm × 1,300mm

| |

Net weight

| 2,000 kg

| 4,500 kg

| |

*Please note that some of the specifications of this machine are subject to change without notice.

Safety technology

In Europe, safety standard is stricter than that in Japan, and the low doesn't permit to import the machine which doesn't acquire CE marking.

Our Rolling Machine cleared all the command of occasion, low voltage, EMC, and its safety technology could be recognized in the world.

Our Rolling Machine cleared all the command of occasion, low voltage, EMC, and its safety technology could be recognized in the world.

Product photograph

Common outer diameter sizing part

of CRF□□-OR

CRF70-OR

CRF120-OR

CRF70V-OR

TCR80V-OR

CRF120V-OR

TCR120V-OR

TCR160VW-OR

TCR180VW-OR